Using a CMMS

Maintenance and reliability professionals can track work activities, parts usage, and asset lifecycle. Labor resources can be maximized through improved planning and scheduling and a reduction of time spent on data entry and unnecessary maintenance tasks.

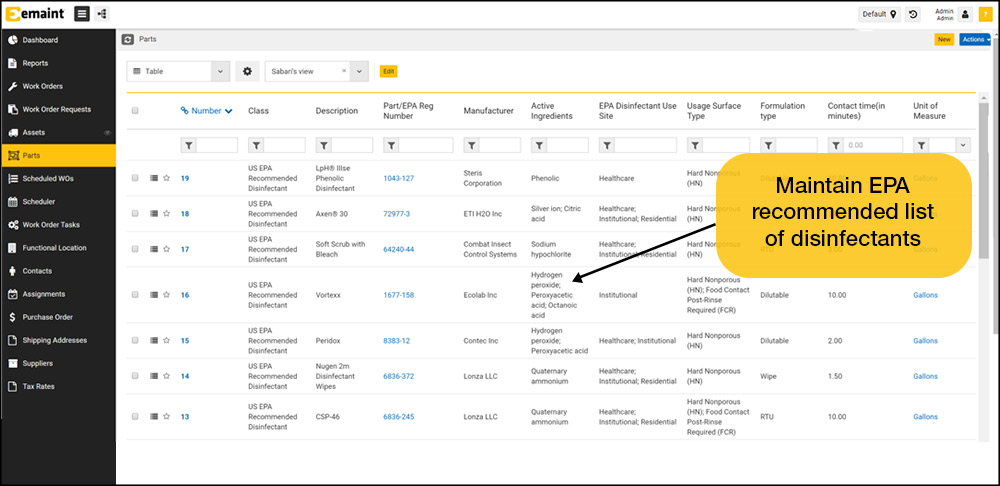

The digital recordkeeping capabilities of software simplify audits and reporting, making staying in compliance faster and easier. When compliance auditors show up for FDA, ISO, SHA, or GMP regulations, there’s no need to scramble. eMaint CMMS from Fluke Reliability helps teams:

- Generate reports and dashboards

- Track work order history, work requests, and calibration

- Attach documents to records and document procedures

- Record labor and hours spent

eMaint CMMS is as mobile as the teams that use it are, allowing members to access information at their fingertips. Users can track key performance measurements, spot trends, report on component failures, and more—no matter where they are working.

Using a CMMS to improve communication and transparency, as well as worker productivity, boosts an organizations efficiency and asset availability. By preventing failures, instead of reacting to them, organizations can maximize uptime and production. With reduced costs and increased uptime potential, maintenance transforms from a drag on budgets to a business value add.

Benefits of a CMMS

In today’s fast-paced business environment, an effective computerized maintenance management system (CMMS) software solution is vital for maintenance teams to succeed at driving operational excellence.

Top 10 benefits of a CMMS:

- Extend the life of assets

- Meet compliance and safety standards

- Increase visibility and transparency

- Improve work completion rate

- Eliminate manual processes

- Reduce maintenance costs

- Increase worker productivity

- Create a paperless environment

- Make data-driven decisions

- Reduce equipment downtime

These 10 benefits represent just part of what is possible with eMaint CMMS. Organizations can also easily access data and insights that make it possible to cut costs and boost revenue, ensure compliance, and optimize uptime and production.

By monitoring and tracking assets, organizations gain a clear picture into real-time asset health and performance. CMMS software helps organizations make data-driven maintenance decisions and reduce asset failures and maintenance costs. The ability to define a Ranking Index Maintenance Expenditure (RIME) ranking makes prioritizing assets simple and enables maintenance teams to streamline how they spend their time and efforts.

Work order management tools increase transparency and visibility, so that team members stay on the same page. Scheduling and work order signoffs become fast and simple, and on-time work completion rates increase. Work requests and work order permitting are easier to track and inventory spending is minimized when organizations have the parts they need on hand—and no longer pay expediting fees when assets go down unexpectedly.

Fully leveraging eMaint CMMS software not only improves maintenance efficiency, but also changes the image of maintenance activities from being a cost center into a business value engine of the company. With an optimized maintenance program, where unplanned downtime and costs are reduced, uptime and productivity are maximized, and asset lifecycles are extended, organizations gain a competitive edge.

How to get the most out of your CMMS

Using a CMMS enables organizations to balance cutting costs while improving productivity and customer satisfaction. However, experts estimate that up to 80% of CMMS implementations fail to meet expectations.

To ensure your CMMS implementation is a success and you get the most out of your system, follow these key steps:

Ensure data integrity

A CMMS is only as good as the data flowing through it. Building an asset hierarchy and collecting complete and accurate data are important factors in maintaining data hygiene.

Invest in training and education

On average, companies actively use only 10-20% of their system’s functionality. Effective training can drastically improve the value you get from your CMMS. Make sure your team is educated by providing core functionality CMMS training (both initial and ongoing).

Document work processes

The more you document within your CMMS, the easier it is to prepare for compliance audits and identify potential failures. Get started by establishing work control functions, defining priority based on criticality and accounting for 100% of labor and parts incurred.

Control budget and cost

Tracking costs within your CMMS enables you to make smarter budgeting decisions. Charge costs to work orders, document cost improvements, and support asset life cycle costing.

Plan and schedule work

Manage your maintenance resources more efficiently by establishing a process for planning and scheduling. Monitor the amount of proactive work and develop work schedules for planned work.

Manage MRO materials

Bridge the maintenance, repair, and operations (MRO) reliability gap by designating critical and/or capital spare parts, tracking warranty information, and documenting processes for refurbishment/repair.

Track and measure KPIs

Transform your CMMS data into meaningful insights and make data-driven decisions. Easily measure key performance indicators (KPIs) such as downtime, labor performance, and wrench time.

Audit processes for continuous improvement

Treat your CMMS as your most valuable asset. Evaluate ongoing improvements each year. Conduct reviews on processes, data, and workflows in order to ensure that you are maximizing your value.